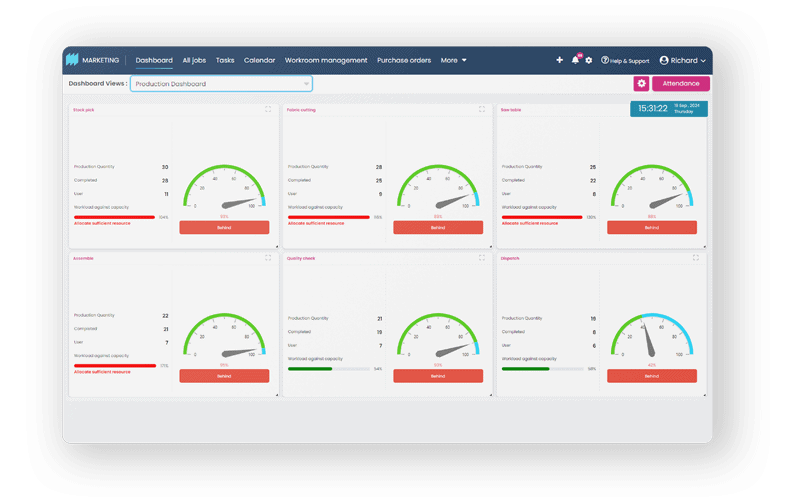

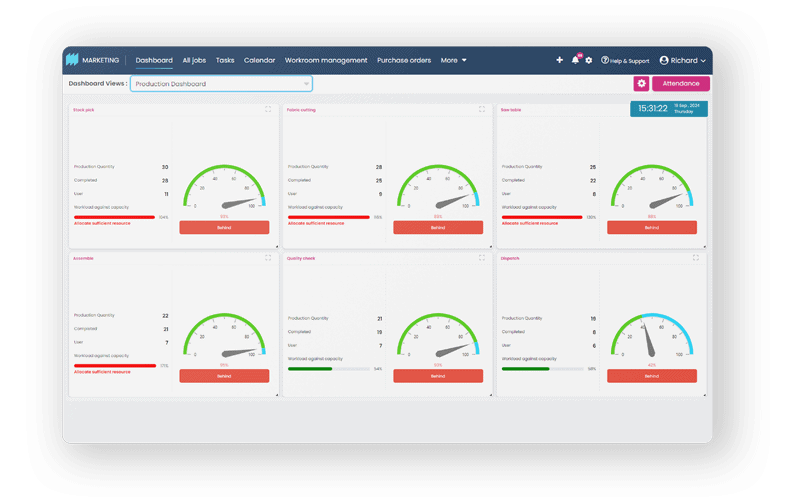

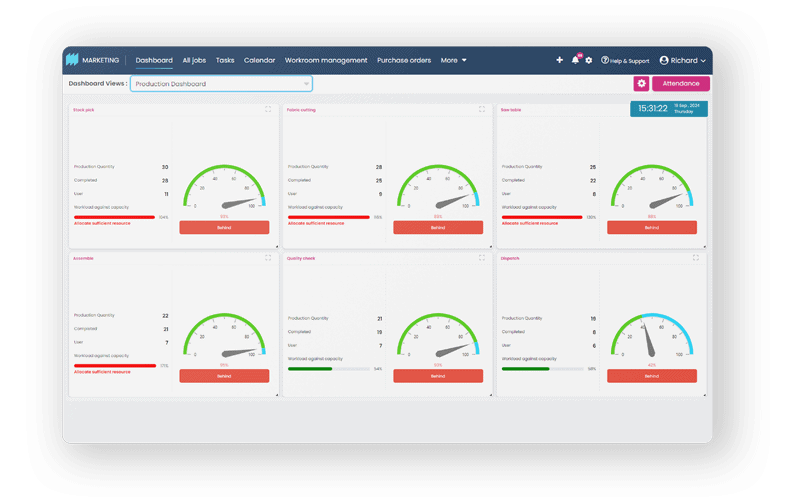

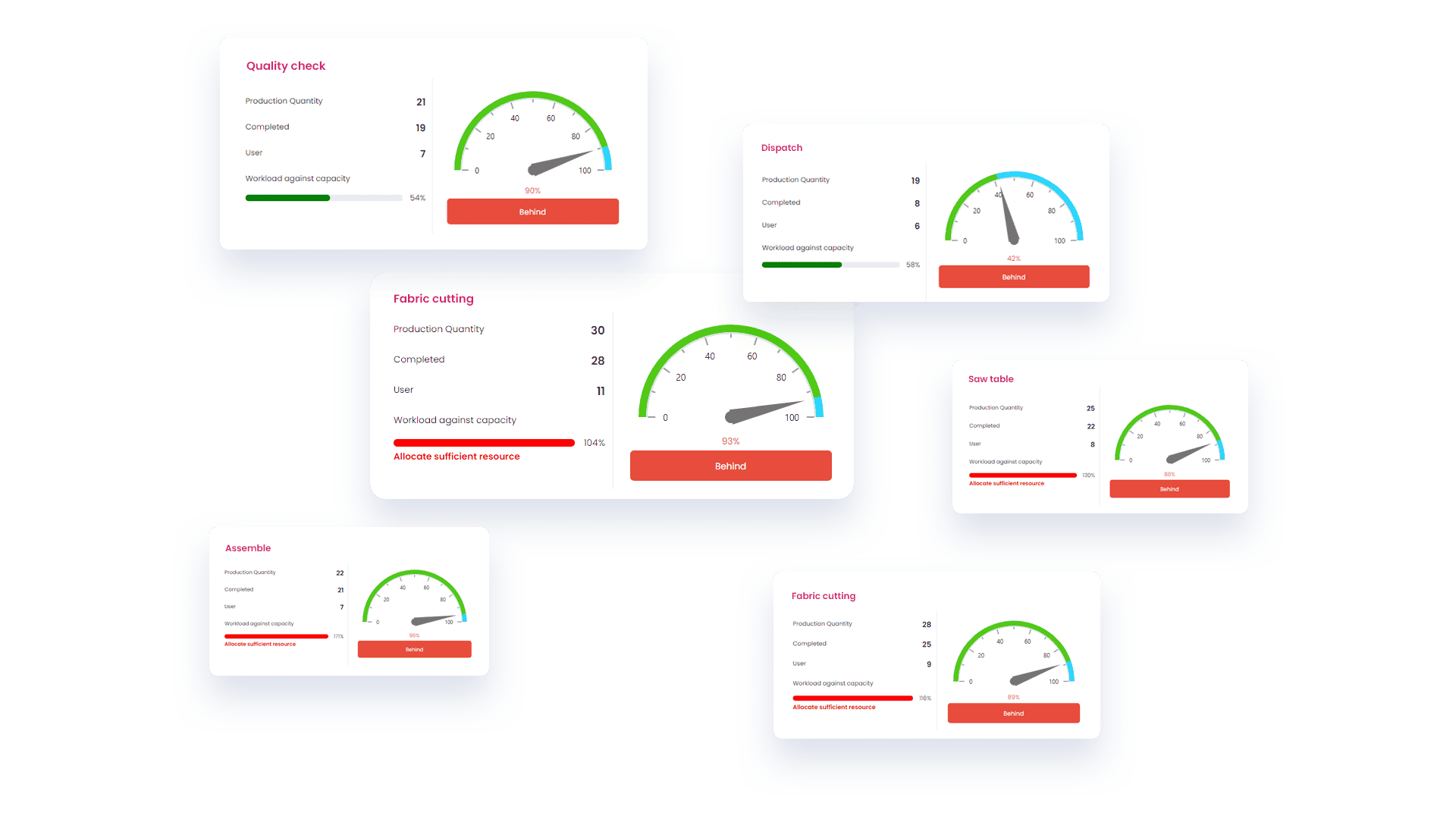

The production manager can track and monitor the live progress of every station to take full control and deliver the products on time.

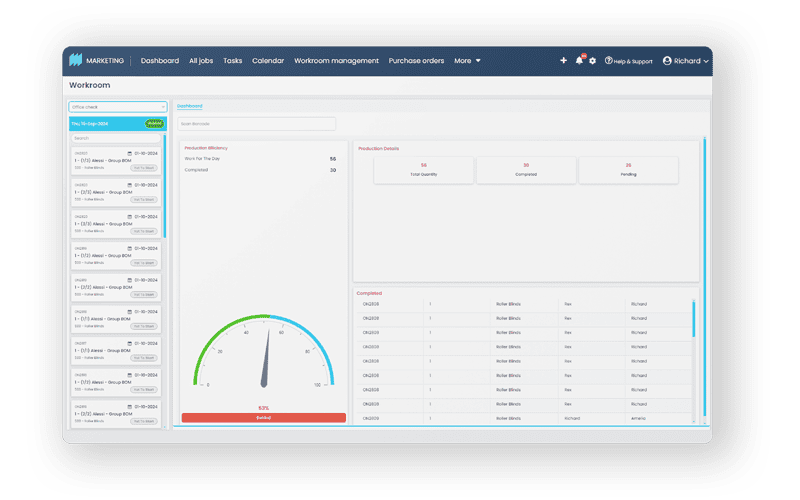

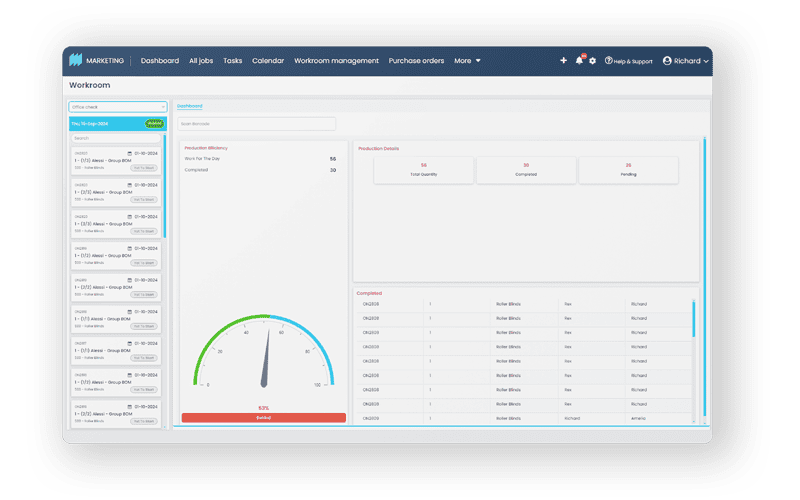

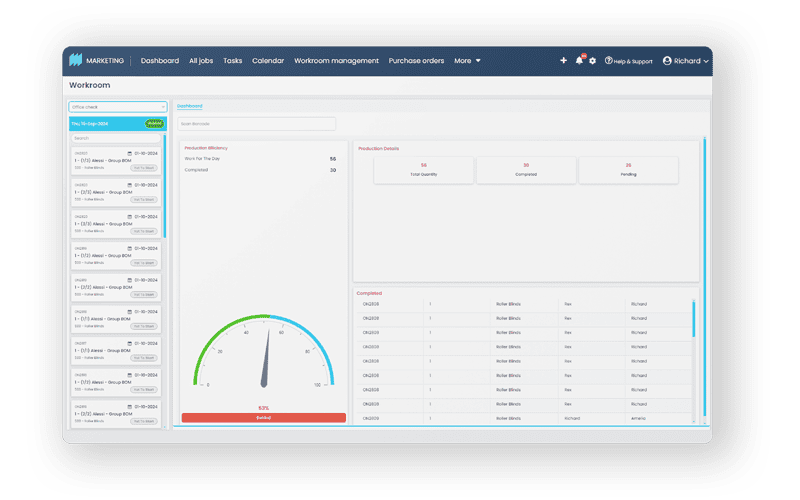

Each factory staff from work station can see their production details like work for the day, jobs completed, pending jobs and total quantity of jobs allotted for them and work accordingly.

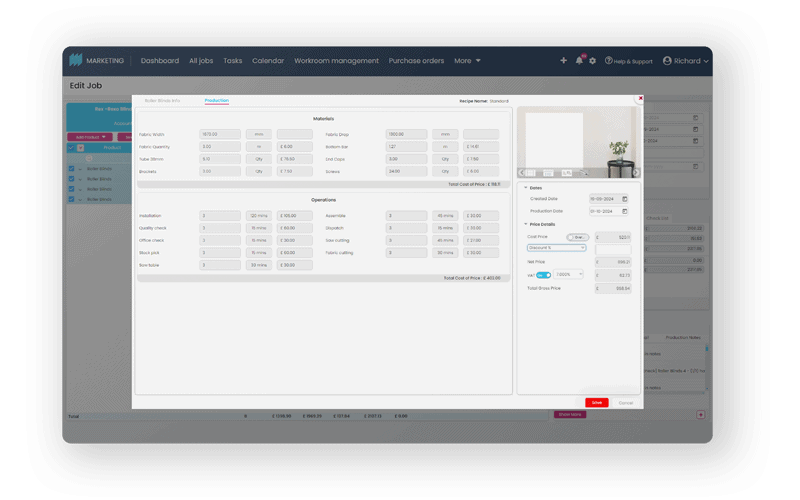

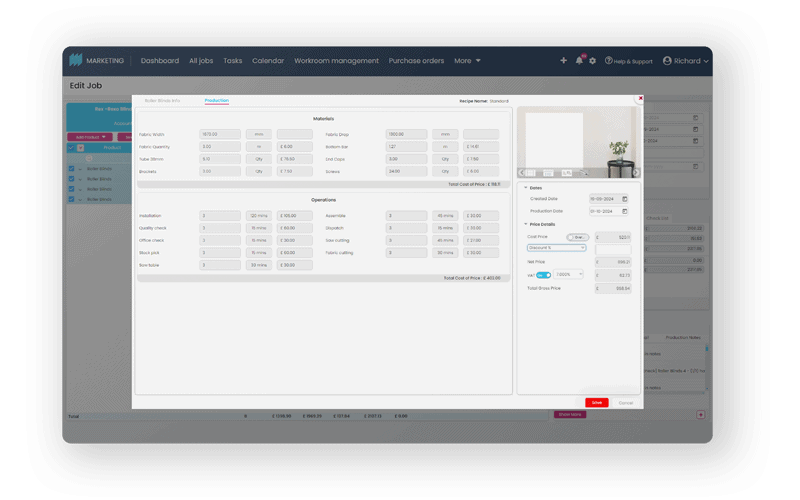

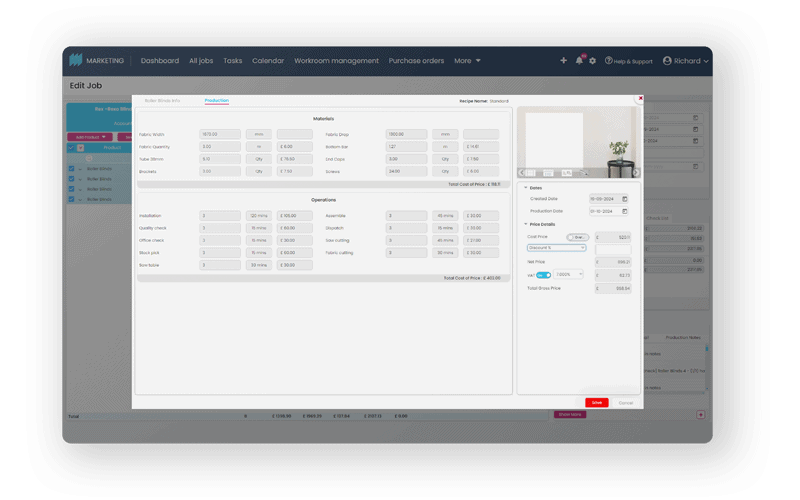

Whenever a new line item is created, staff can instantly see all the raw materials that will be used to manufacture that item. This provides clear visibility of stock availability, and if something is out of stock, a purchase order will be raised automatically.

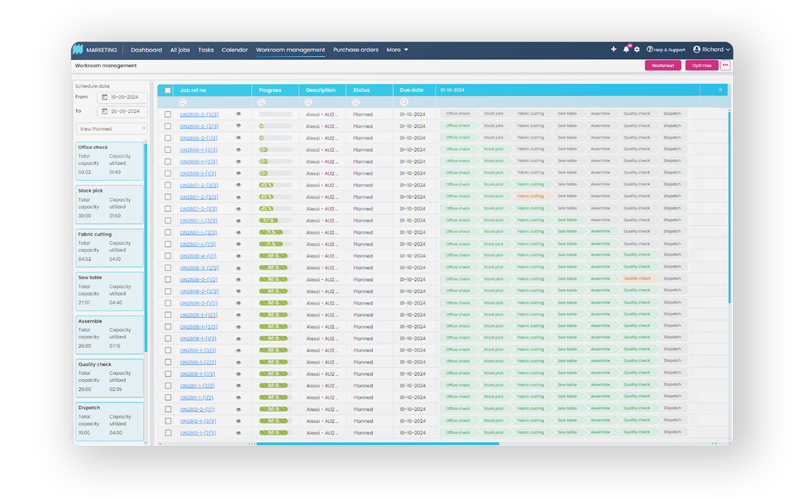

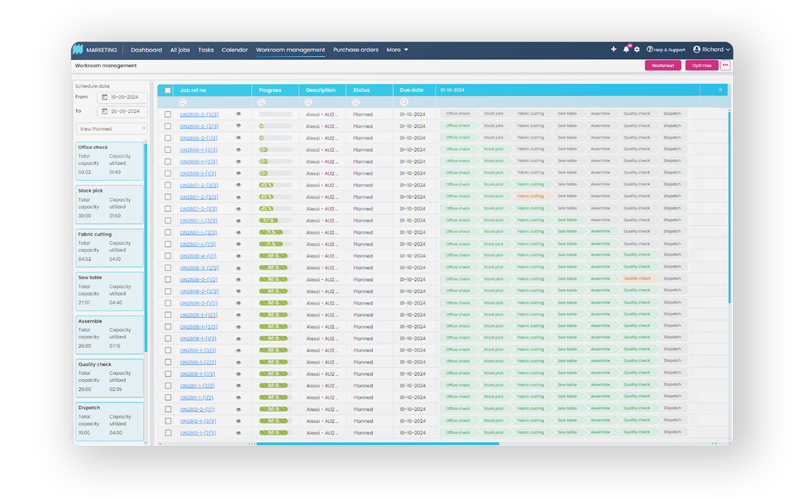

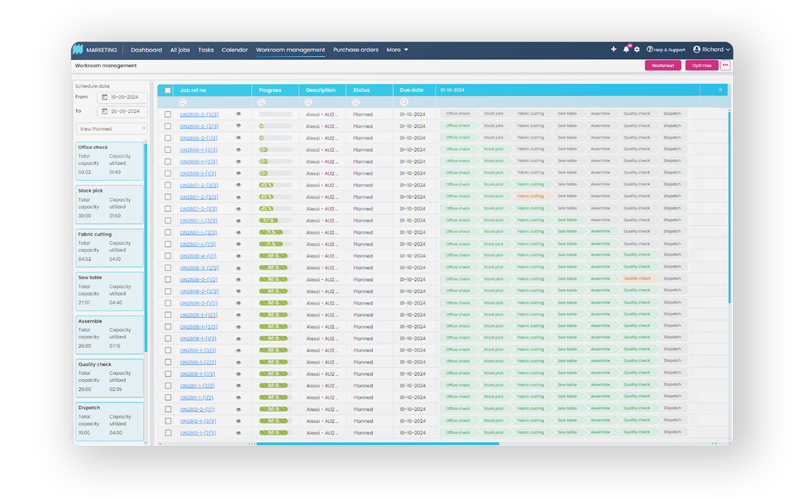

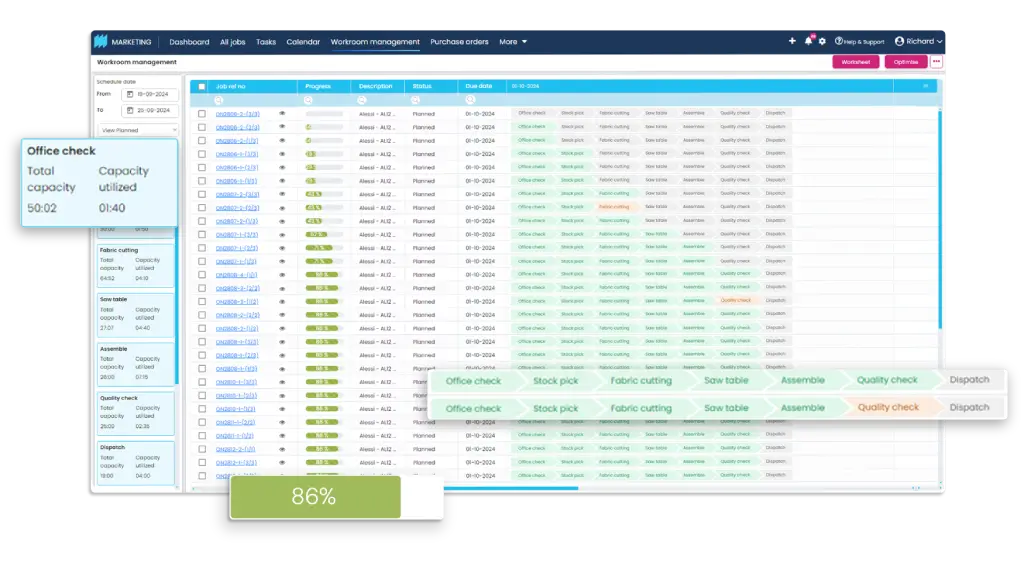

BlindMatrix production management provides a clear view of the entire production progress, status, and due dates on a single screen, with station-wise colour-coded labels indicating the progress level of each line item for streamlined production.

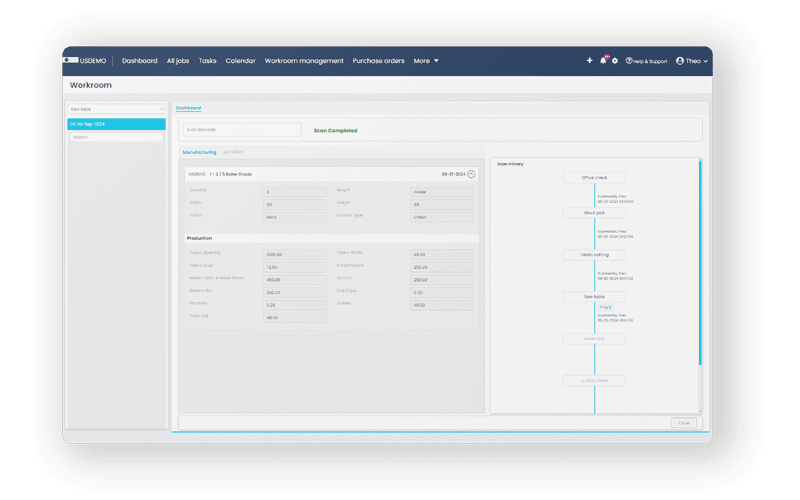

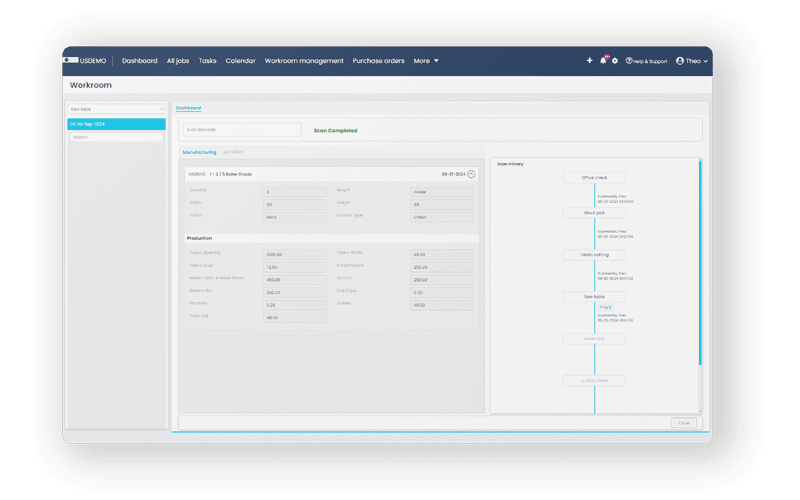

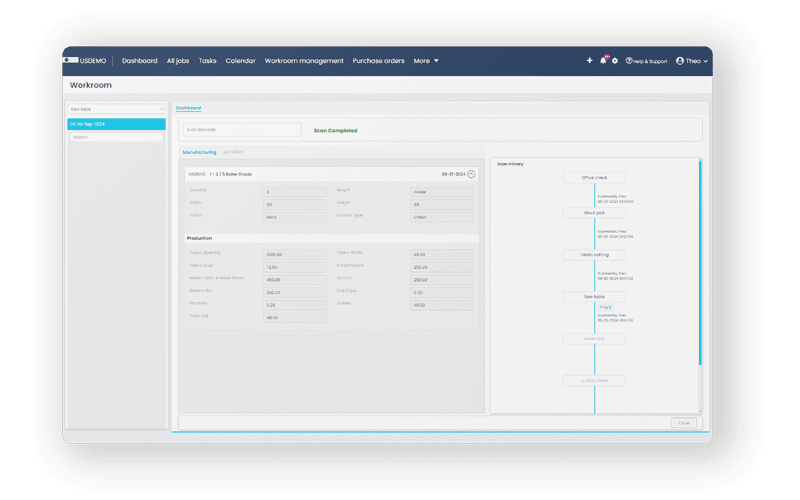

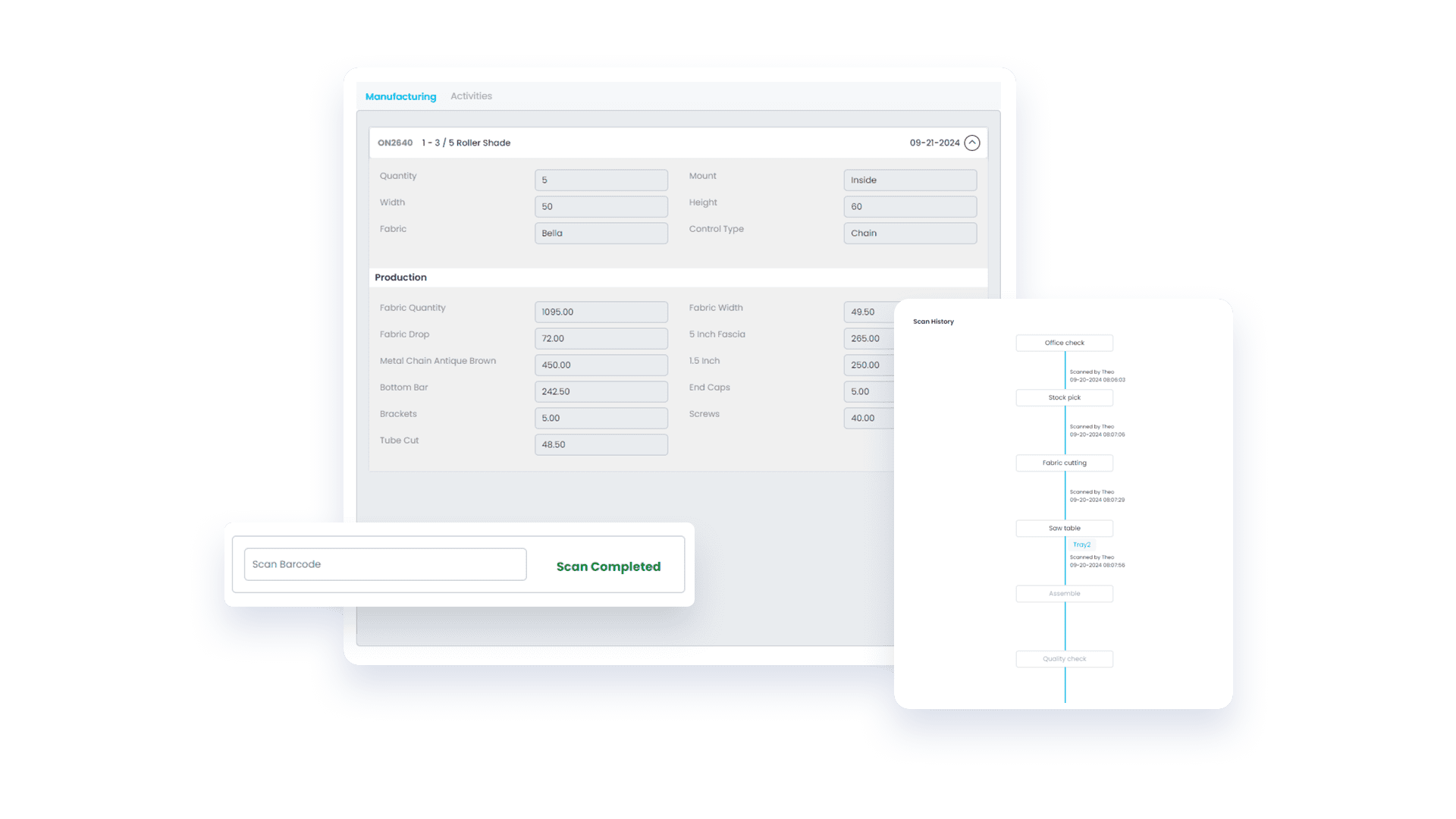

At every work station, BlindMatrix provides your staff with digital manufacturing worksheets with calculated outputs, generated by predefined algorithms to ensure accuracy and efficiency. These calculations help reduce manual errors, ensuring every step of manufacturing is precise and well-coordinated for optimal output.

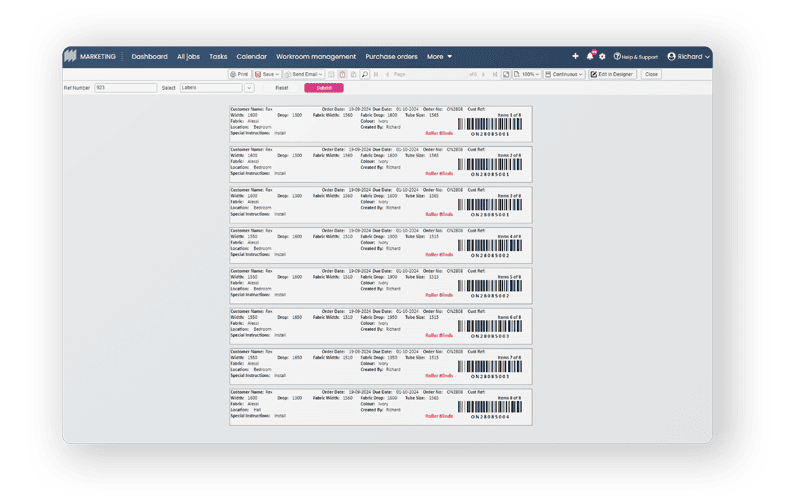

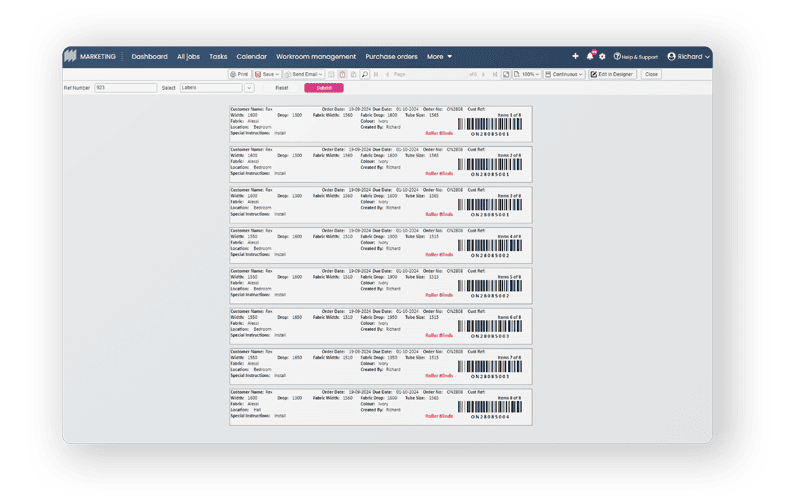

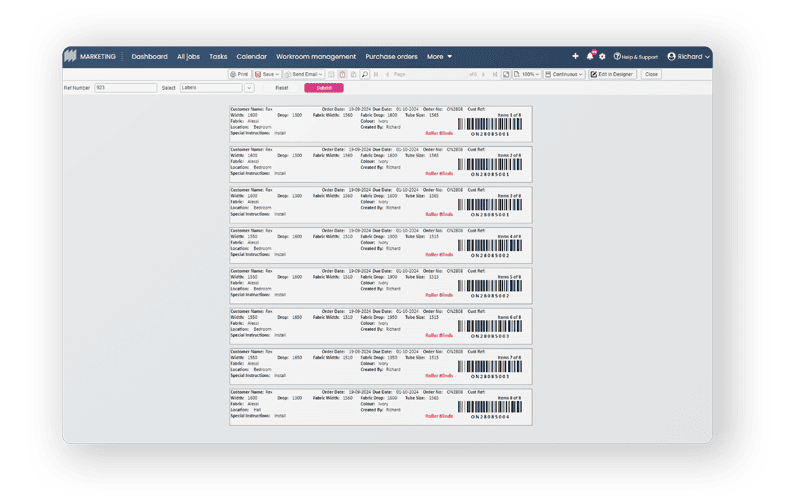

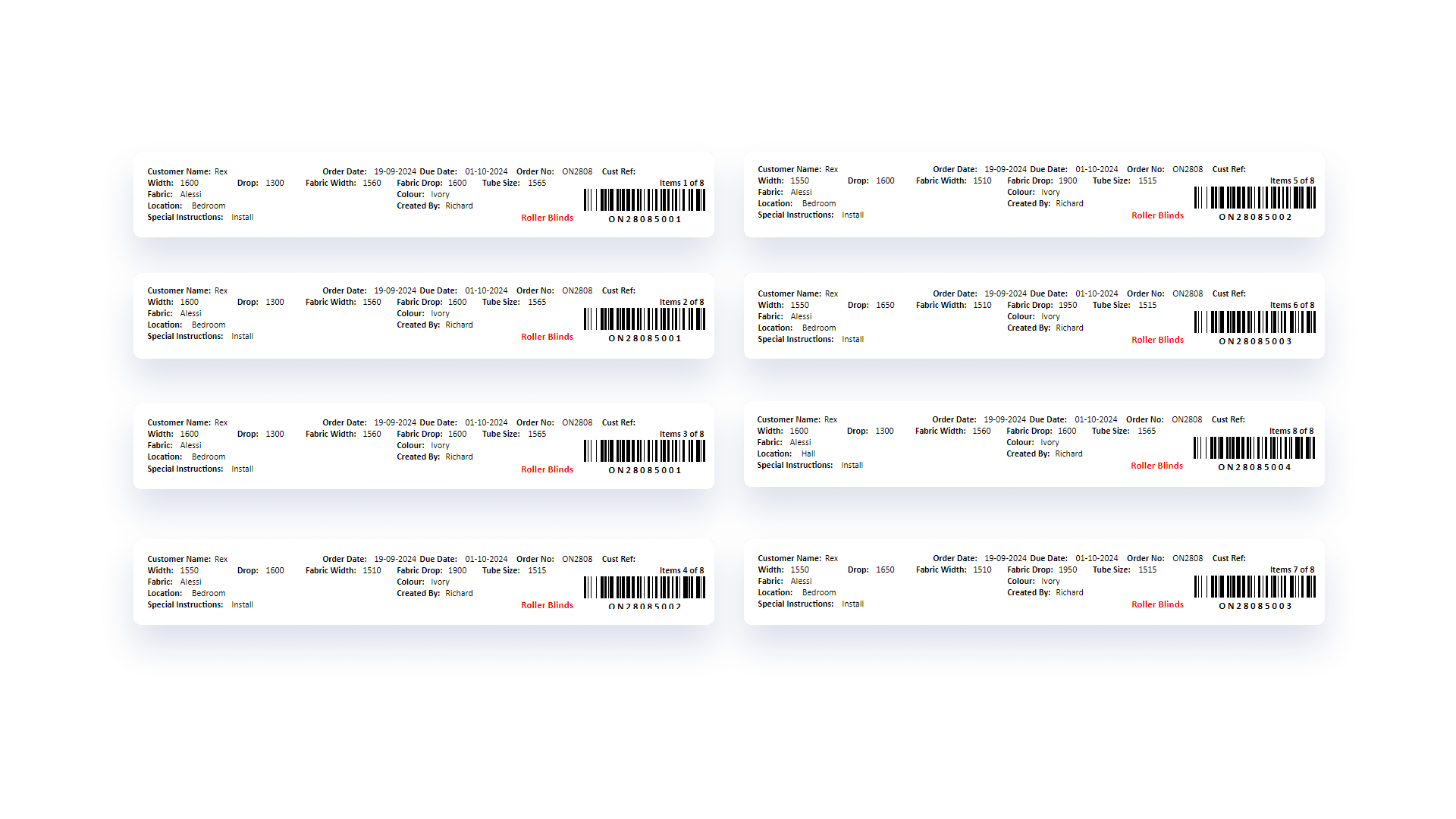

BlindMatrix generates a unique barcode for each line item, providing a distinct identifier to track and assemble products at every stage.

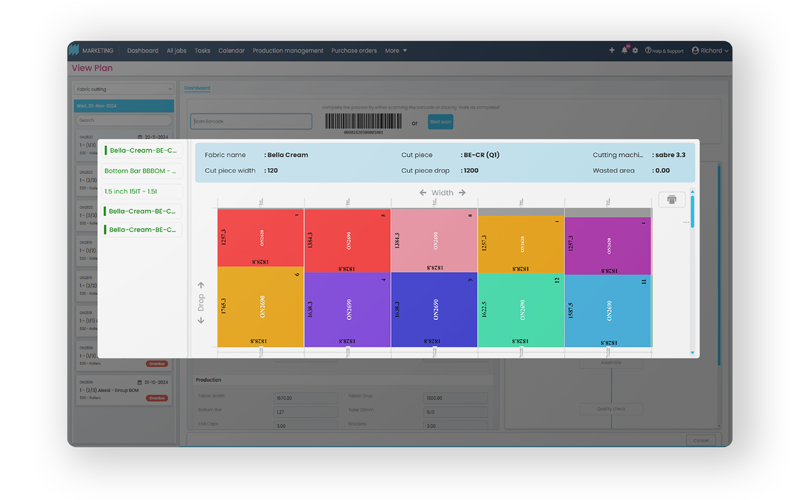

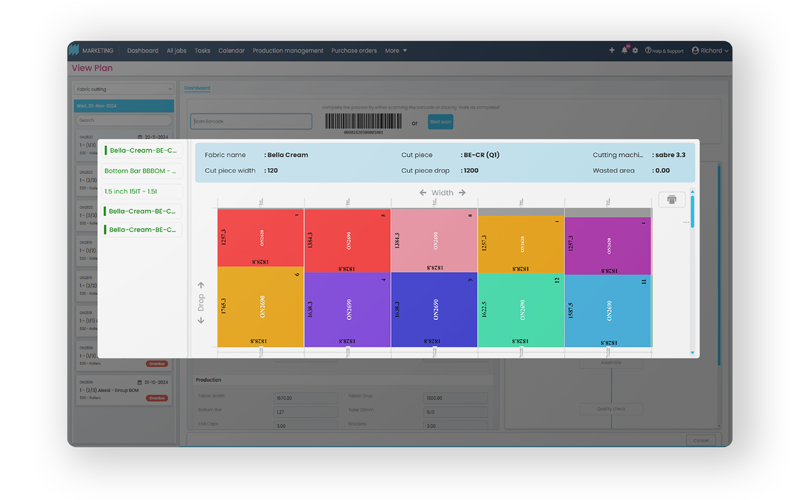

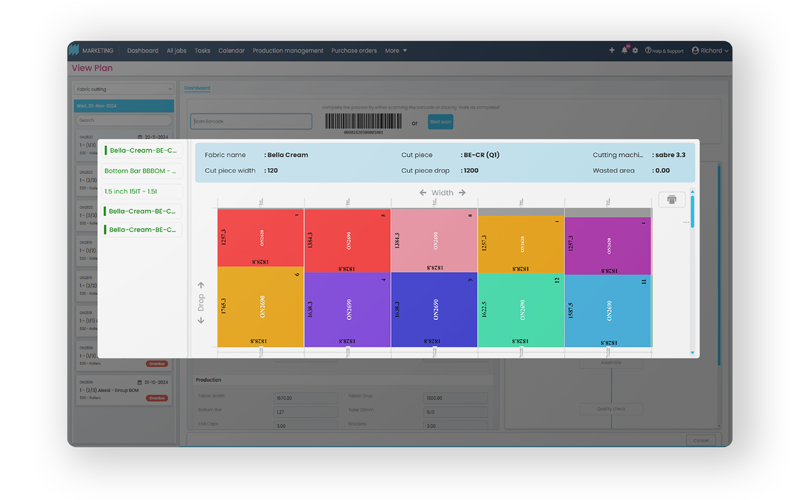

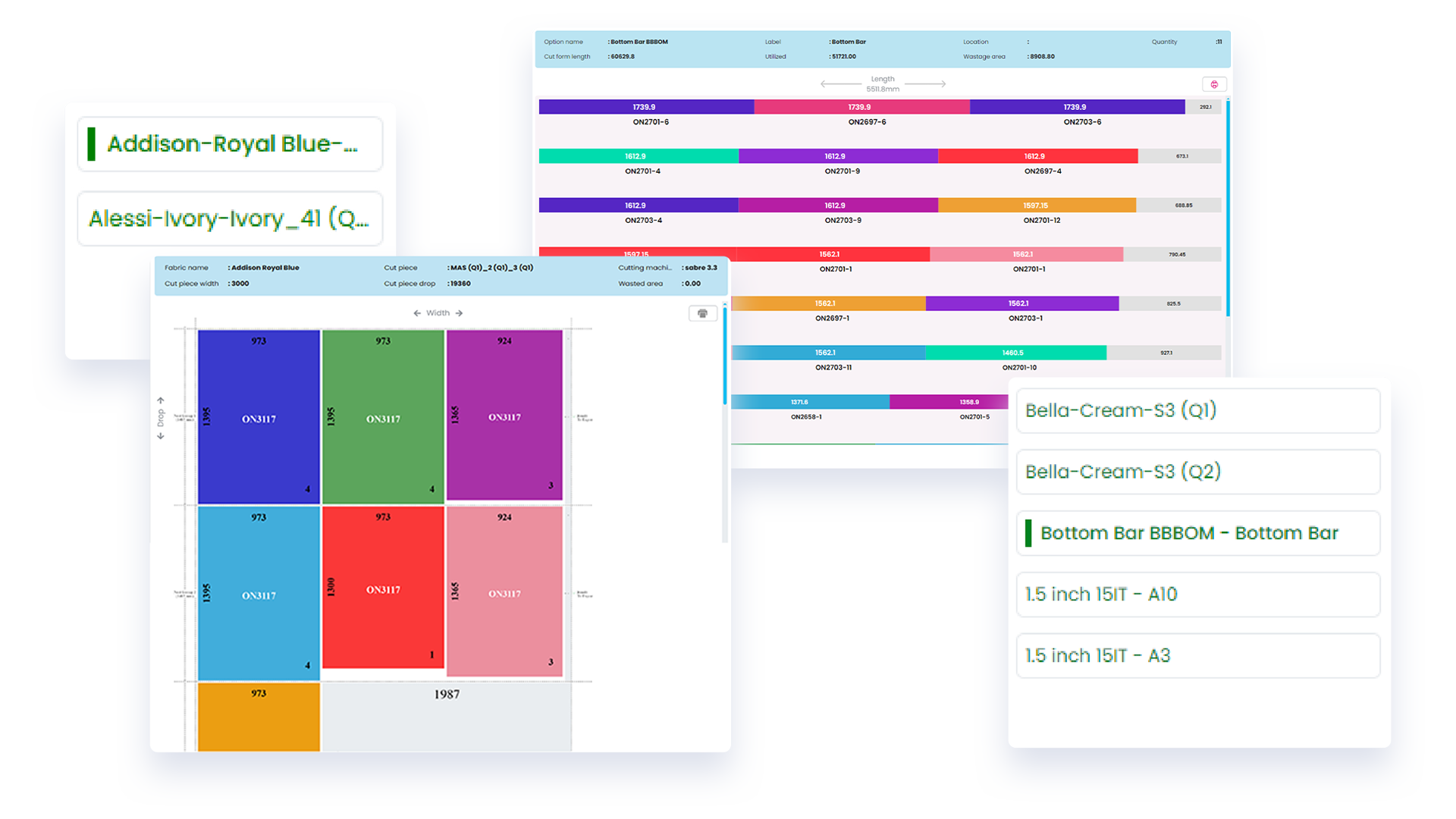

BlindMatrix eliminates guesswork, maximises efficiency, and drastically reduces fabric and tube waste by generating intelligent cutting plans using cutting-edge technology. BlindMatrix can also integrate with your cutting machines, making the cutting process fully automatic for improved accuracy.

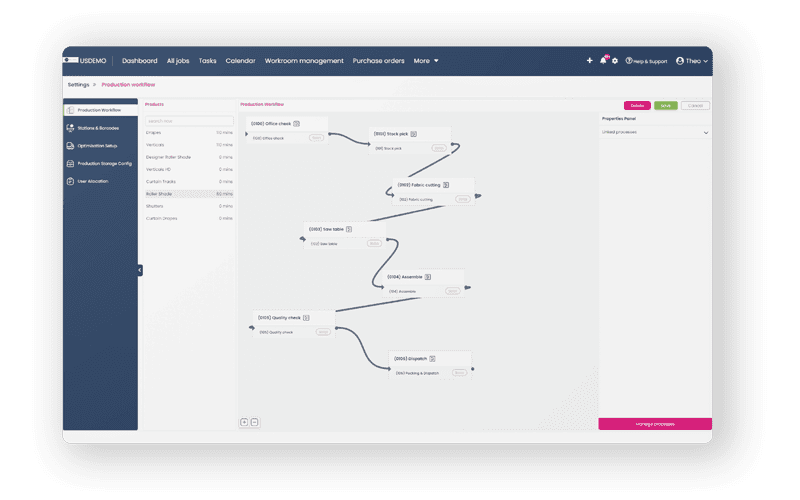

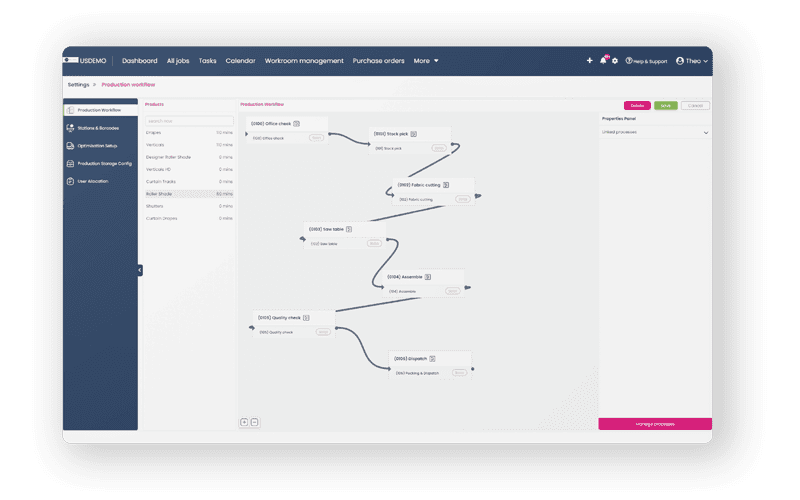

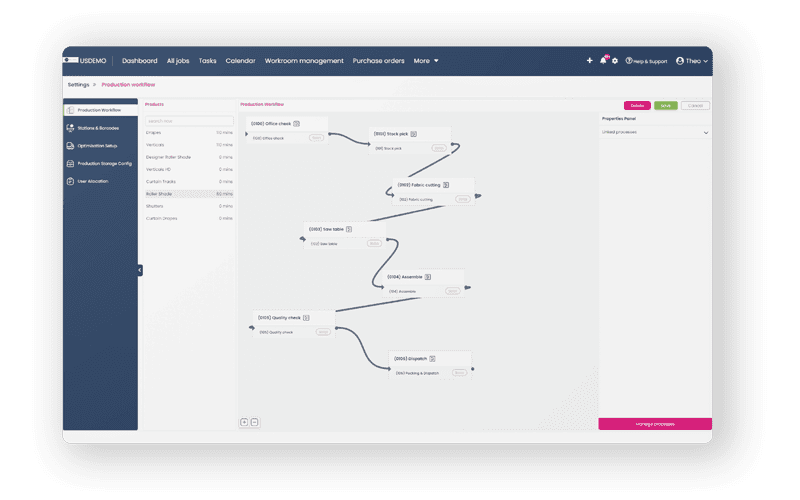

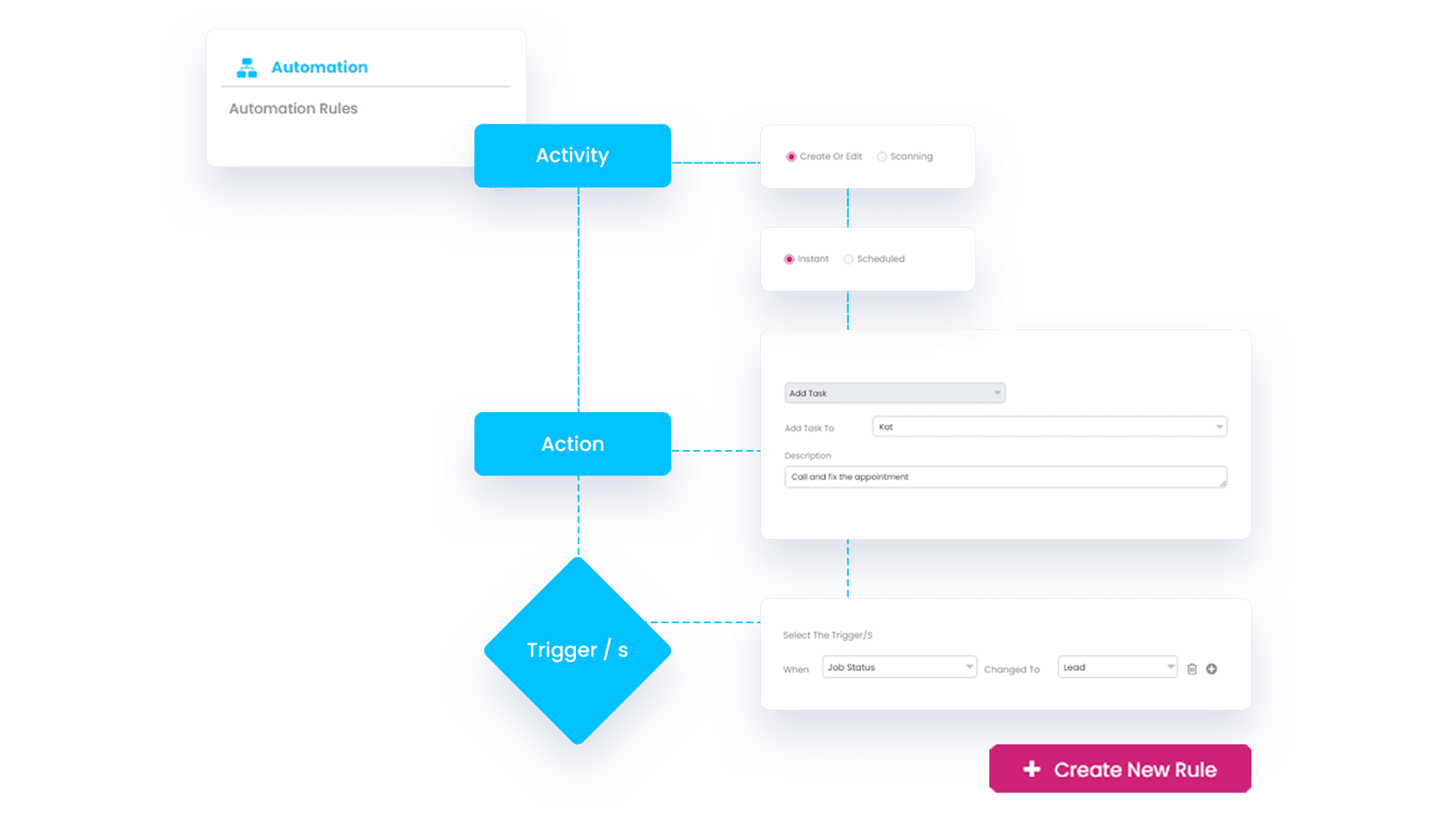

With BlindMatrix, you can now automate your production workflows. The software enables you to define distinct manufacturing processes for different products and set the average time required for production. Due dates are automatically generated based on your production capacity, streamlining the entire process.

The production manager can track and monitor the live progress of every station to take full control and deliver the products on time.

Each factory staff from work station can see their production details like work for the day, jobs completed, pending jobs and total quantity of jobs allotted for them and work accordingly.

Whenever a new line item is created, staff can instantly see all the raw materials that will be used to manufacture that item. This provides clear visibility of stock availability, and if something is out of stock, a purchase order will be raised automatically.

BlindMatrix production management provides a clear view of the entire production progress, status, and due dates on a single screen, with station-wise colour-coded labels indicating the progress level of each line item for streamlined production.

At every work station, BlindMatrix provides your staff with digital manufacturing worksheets with calculated outputs, generated by predefined algorithms to ensure accuracy and efficiency. These calculations help reduce manual errors, ensuring every step of manufacturing is precise and well-coordinated for optimal output.

BlindMatrix generates a unique barcode for each line item, providing a distinct identifier to track and assemble products at every stage.

BlindMatrix eliminates guesswork, maximises efficiency, and drastically reduces fabric and tube waste by generating intelligent cutting plans using cutting-edge technology. BlindMatrix can also integrate with your cutting machines, making the cutting process fully automatic for improved accuracy.

With BlindMatrix, you can now automate your production workflows. The software enables you to define distinct manufacturing processes for different products and set the average time required for production. Due dates are automatically generated based on your production capacity, streamlining the entire process.

The production manager can track and monitor the live progress of every station to take full control and deliver the products on time.

Each factory staff from work station can see their production details like work for the day, jobs completed, pending jobs and total quantity of jobs allotted for them and work accordingly.

Whenever a new line item is created, staff can instantly see all the raw materials that will be used to manufacture that item. This provides clear visibility of stock availability, and if something is out of stock, a purchase order will be raised automatically.

BlindMatrix production management provides a clear view of the entire production progress, status, and due dates on a single screen, with station-wise colour-coded labels indicating the progress level of each line item for streamlined production.

At every work station, BlindMatrix provides your staff with digital manufacturing worksheets with calculated outputs, generated by predefined algorithms to ensure accuracy and efficiency. These calculations help reduce manual errors, ensuring every step of manufacturing is precise and well-coordinated for optimal output.

BlindMatrix generates a unique barcode for each line item, providing a distinct identifier to track and assemble products at every stage.

BlindMatrix eliminates guesswork, maximises efficiency, and drastically reduces fabric and tube waste by generating intelligent cutting plans using cutting-edge technology. BlindMatrix can also integrate with your cutting machines, making the cutting process fully automatic for improved accuracy.

With BlindMatrix, you can now automate your production workflows. The software enables you to define distinct manufacturing processes for different products and set the average time required for production. Due dates are automatically generated based on your production capacity, streamlining the entire process.

blinds businesses of all sizes

Got a business challenge or question about our solutions? We have tailored solutions ready to meet your needs. Let’s discuss how we can address your challenges and drive your business growth.